The Pavement Preservation Process

March 1, 2021

Why Hiring an ADA Contractor is Important

April 2, 2021 When choosing a material for commercial or residential projects, you want to go with the one that offers long-term value. Asphalt paving is a superior material suitable for a wide variety of projects. It offers numerous advantages over pavement surfaces constructed using other materials. 94% of the American roads are surfaced with asphalt and it is no surprise why. Asphalt pavements offer high skid resistance, promote water drainage, incredibly durable, affordable, easy to install, attractive, and environmentally friendly.

When choosing a material for commercial or residential projects, you want to go with the one that offers long-term value. Asphalt paving is a superior material suitable for a wide variety of projects. It offers numerous advantages over pavement surfaces constructed using other materials. 94% of the American roads are surfaced with asphalt and it is no surprise why. Asphalt pavements offer high skid resistance, promote water drainage, incredibly durable, affordable, easy to install, attractive, and environmentally friendly.

Here in the blog post, we will explain everything you need to know about asphalt paving.

What is Asphalt?

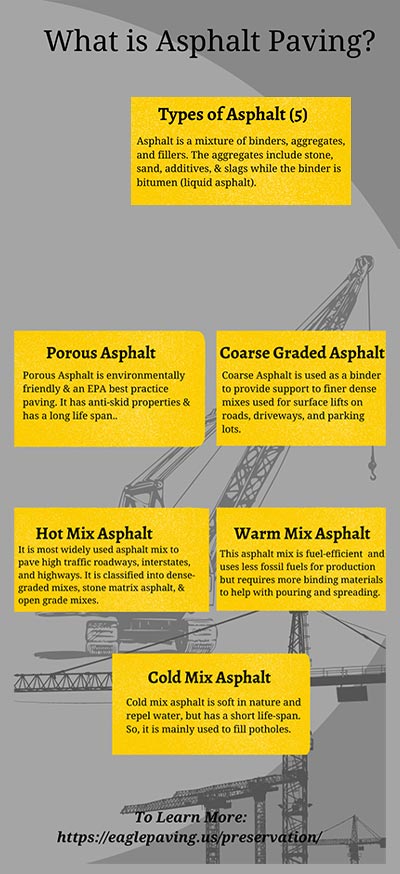

Asphalt is a mixture of binders, aggregates, and fillers. The aggregates include stone, sand, additives, and slags. The binder is bitumen or liquid asphalt (sticky black substance) to hold the aggregates together. It is viscous and can also be found in semi-solid form.

All the ingredients are measured, mixed, and baked together to form the final asphalt product. The asphalt paving mixture consists of 90 to 95% aggregate and sand, and 5 to 10% asphalt or bitumen.

Asphalt paving has high viscosity and flexibility offering the pavement the strength that allows the surface to adapt to changing conditions produced by the weather.

Types of Asphalt

Asphalt aggregates are easy to customize, so, you can find hundreds of potential mixes to help meet your specific asphalt need. Various asphalt contractors have their asphalt production plants to create better solutions for your needs. There are four different types of asphalt paving you can find.

Porous Asphalt

Porous asphalt is used since the mid-1970s as it is environmentally friendly and is an EPA best practice paving. This type of asphalt is used in parking lots as it absorbs the water offering anti-skid properties. The pavement solution is cost-effective and can last for more than twenty years.

Coarse Graded Asphalt

This type of asphalt mix is coarse and used as a binder to provide support to finer dense mixes that are typically used for surface lifts on roads, driveways, and parking lots. These mixtures are typically known as binder mixtures.

Cold Mix Asphalt

Cold mix asphalt stays soft in cold temperatures and repels water. It is mainly used for pothole repairs. As this mixture has a soft nature, it tends to have a short life-span and is used as a temporary measure for repairs.

Hot Mix Asphalt

By far the most widely used asphalt mix is the hot mix. The mix is heated and poured at temperatures between 300 and 350° F and is used to pave high traffic roadways, interstates, and highways. It is further classified into three categories, such as dense-graded mixes, stone matrix asphalt, and open grade mixes.

Warm Mix Asphalt

This asphalt mix is manufactured between 200 and 250° F and is a more fuel-efficient option than hot mix. The production of this mix uses fewer fossil fuels but requires more binding materials to help with pouring and spreading.

Asphalt Pavement Installation

A new asphalt installation is a new start to your pavement. It follows a 6-step process that includes demolition and removal of the existing surface, grading and sloping that helps water to drain away from the pavement, preparing the sub base to support new pavement, adding the binder layer to make it strong and durable, installing the new asphalt surface, and the final roll to smooth out the surface.